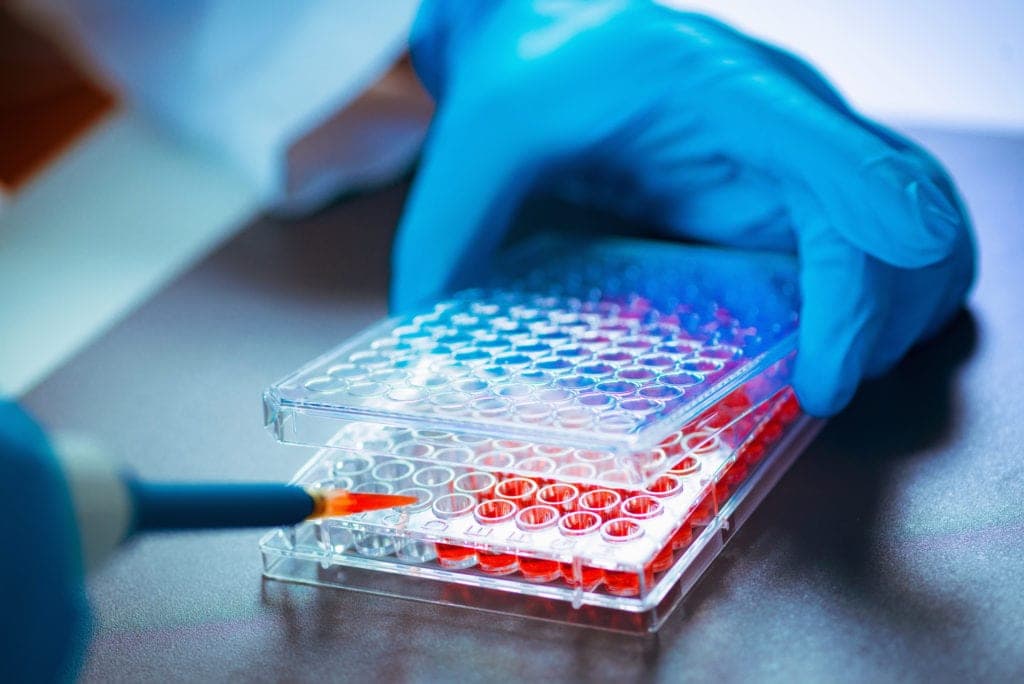

The field of tissue engineering has seen remarkable advancements, with 3D bioprinting emerging as a transformative technology. This innovation, which combines the principles of engineering and biology, allows for the creation of complex tissue structures using biomaterials. Biomaterials are crucial in this process, serving as the building blocks that support cell growth and tissue formation.

The Foundation of 3D Bioprinting: Biomaterials

Biomaterials are substances engineered to interact with biological systems for therapeutic or diagnostic purposes. In 3D bioprinting, these materials are used to create scaffolds that provide a supportive structure for cells to grow and develop into tissues. “Biomaterials are the cornerstone of tissue engineering; they provide the physical and biochemical environment needed for cells to function and thrive,” says Dr. Emily Wang, a leading researcher in biomaterials science.

These materials must possess certain properties to be effective in bioprinting. They need to be biocompatible, ensuring they do not provoke an immune response, and bioactive, meaning they can support cellular activities such as adhesion, proliferation, and differentiation. “The choice of biomaterial can significantly impact the success of the bioprinting process and the functionality of the engineered tissue,” notes Mark Thompson from palms bet bg.

Types of Biomaterials Used in 3D Bioprinting

Several types of biomaterials are used in 3D bioprinting, each offering unique advantages:

Hydrogels: Hydrogels are highly absorbent polymers that can retain a large amount of water, making them similar to natural tissue. “Hydrogels are popular in bioprinting because of their tunable properties and ability to mimic the extracellular matrix,” explains Dr. Sarah Lee, a materials scientist. They can be engineered to provide mechanical support and deliver growth factors, which are essential for tissue development.

Biopolymers: Biopolymers such as collagen, fibrin, and gelatin are derived from natural sources and are known for their biocompatibility and biodegradability. “Biopolymers are ideal for creating scaffolds that degrade over time, allowing the natural tissue to replace the engineered structure,” says Dr. Michael Green, a biopolymers specialist. This property is particularly important in applications like wound healing and organ regeneration.

Synthetic Polymers: Synthetic polymers like polylactic acid (PLA) and polyglycolic acid (PGA) are also used due to their customizable properties. “Synthetic polymers can be precisely engineered to achieve specific mechanical and chemical characteristics, making them versatile for various bioprinting applications,” highlights Dr. Laura Smith, a chemical engineer.

Innovations and Challenges in Biomaterial Development

Recent innovations in biomaterial development have focused on enhancing the functionality and versatility of these materials. For example, researchers are exploring the use of smart biomaterials that can respond to environmental stimuli, such as changes in temperature or pH, to release drugs or growth factors. “Smart biomaterials represent a new frontier in tissue engineering, offering dynamic control over the tissue microenvironment,” states Dr. David Chan, an innovator in biomaterials research.

However, challenges remain in the field, particularly in scaling up the production of biomaterials and ensuring consistency in quality. “One of the biggest hurdles is translating laboratory-scale biomaterials to clinical applications, where large quantities and rigorous safety standards are required,” notes Dr. Jessica Brown, a regulatory scientist.

Additionally, the integration of biomaterials with living cells poses significant technical challenges. Maintaining cell viability and function during the bioprinting process is critical. “Ensuring that cells remain viable and retain their functional properties post-printing is essential for the success of tissue engineering,” emphasizes Dr. Karen Johnson, a cellular biologist.

Future Directions and Applications

The future of biomaterials in 3D bioprinting holds exciting potential for medical and therapeutic applications. One of the most promising areas is organ printing, where fully functional organs could be printed and transplanted, addressing the shortage of donor organs. “The ultimate goal is to create patient-specific tissues and organs that can replace damaged ones, offering a personalized approach to medicine,” says Dr. Alex Lee, a pioneer in organ bioprinting.

Another emerging application is the use of bioprinted tissues for drug testing and disease modeling, providing more accurate and ethical alternatives to animal testing. “Bioprinted tissues can mimic the complexity of human organs, offering a better platform for testing drug efficacy and toxicity,” explains pharmaceutical researcher Dr. Maria Lopez.

Biomaterials play a pivotal role in the advancement of 3D bioprinting and tissue engineering. Their development and refinement are crucial for creating functional and clinically viable tissues. As research continues to push the boundaries of what is possible, biomaterials will undoubtedly remain at the forefront of innovation, paving the way for breakthroughs in regenerative medicine and beyond. As Dr. Emily Wang aptly puts it, “The intersection of biology, engineering, and materials science in bioprinting offers unparalleled opportunities to transform healthcare and improve lives.”